Faux Brick 2-Post Assembly Instructions

A few of the photos below show our New England Style sign, but your assembly steps are similar with your stone/brick columns.

Step 1

Unpack everything from the skid and or boxes they are packed in. If you lay your sign on the ground, to protect it from getting scratched use the foam or cardboard wrapping material that your sign was packed in.

Step 2

There is a hollow PVC post mounted inside your faux stone/brick columns. These photos do not show the stone/brick columns, but assembly is the same. Insert sign side”tabs” into pre-cut channels in top of your faux brick/stone columns (on both sides).

Step 3

Insert special “clips” as shown down into both post tops.

Step 4

Screw top of clip down to top of sign “tab” on inside of posts.

Step 5

Now that your sign structure is fully assembled, purchase two wood treated treated lumber locally and cut them to proper length. Remember the bottom of your wood posts will be buried below frost line in your area (or to meet local zoning requirements). Slide the precut wood posts up into bottom of your post columns in the 4″x4″ space provided inside posts.

Option A

Purchase four treated wood 2×4’s from your local lumber yard. These will be buried in the ground (below frost line in your area) and extend up into the hollow PVC post sleeves that are mounted inside your faux stone/brick columns. Screw them together as shown in photo #1. The inside 2×4 should only come up to within 2″ below the bottom of the sign “tab” inside your PVC post sleeve (the sign “tab” should net be resting on top of the inside 2×4). The outside 2×4 should be trimmed to end up about 8″ below the top of the PVC post sleeve.

Option B

You could also use two wood/treated 4×4’s instead of four 2×4’s in this step. The height of your 4×4 will need to be trimmed to go up into your sign post and end about an inch below the bottom part of your sign “tab”.

Step 6

Lay sign down and slide treated wood posts up into bottom of sign posts.

Step 7

Pre-drill holes on inside of sign posts near bottom. Insert stainless steel screws.

Step 8

Dig your 2 holes spaced accordingly for your post bottoms.

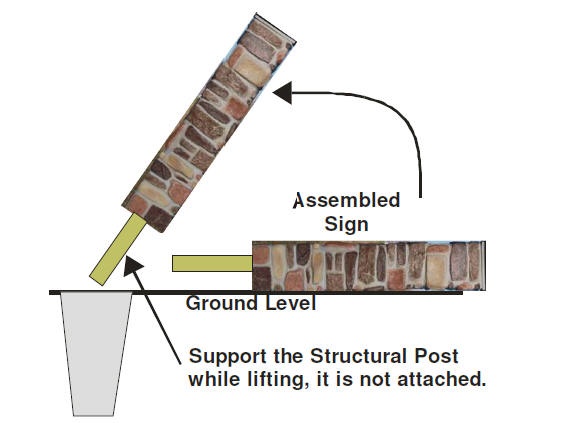

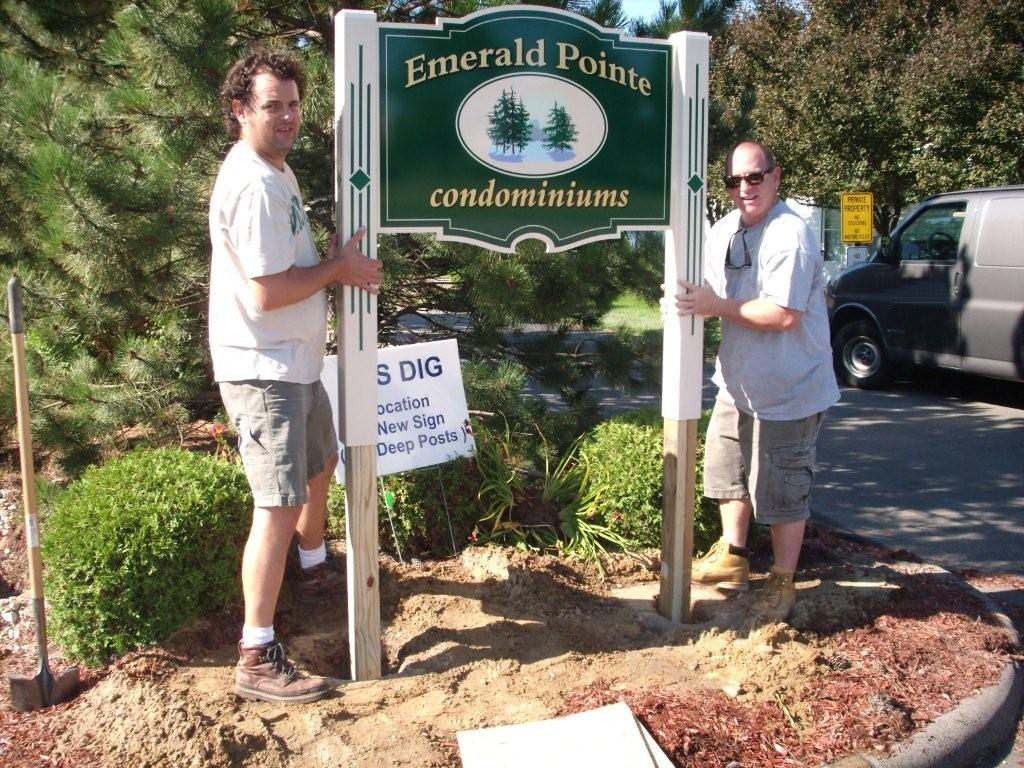

Step 9

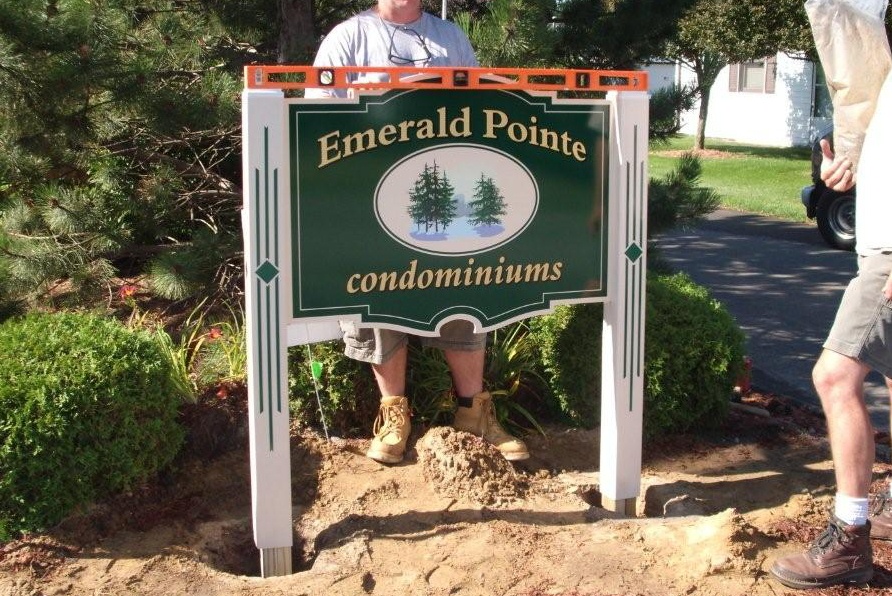

Pick up entire sign and carefully lower into holes (2 people are required for this size sign). Check for level and straighten accordingly.

For this larger size sign, you may choose to add “post-hole” concrete to your holes prior to backfilling with the dirt. (“Post Hole concrete” does not need to be premixed, you can just pour into your hole straight from the bag and then pour water on top of it, it will harden up on its own then.)

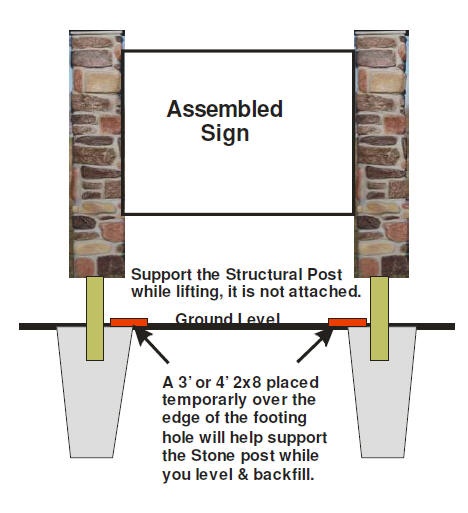

Step 10

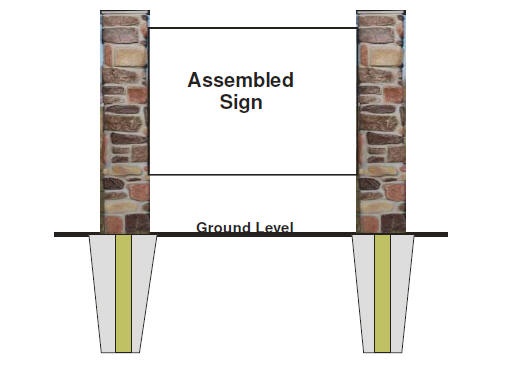

You can see in the diagram below that placing a temporary wood piece across the top of your hole will keep the stone post from falling into your hole (until you backfill your holes).

Step 11

When done backfilling your holes (dirt or cement, whichever is required) remove the temporary wood supports and let the brick posts drop down to ground level and rest on the ground. We recommend at least a bag or two of “post hole cement” in each hole prior to backfilling (or whatever your local code requires). “Post Hole Cement” does not require premixing, just pour it into your hole and then add water on top of it. Will harden and cure on its own then, no need for messy premixing.

Step 12

Backfill your holes. Install post caps and your sign is complete!

Step 13

If you purchased an optional sign “rider” for your sign, they get installed after your sign is completed assembled (see steps 1-9 above). There are aluminum angle brackets that get screwed to the side posts, your sign then attaches to the brackets using the screws provided. A 1 sided sign rider will have 1 bracket per side. A 2-sided sign rider will have 2 brackets per side. See pics below.